The noise level of the Mini Stirrer during operation is typically measured in decibels (dB). The exact noise level can vary based on the specific model and brand of the Mini Stirrer. To ensure a quieter working environment, implement various noise reduction techniques. These may include:

1.Improved Motor Design:

Manufacturers invest in research and development to design motors with advanced technology, such as brushless DC motors. These motors are inherently quieter due to the absence of brushes, reducing friction and noise. Additionally, the motor's internal components are meticulously engineered to ensure smooth operation, minimizing vibrations that can cause noise.

2.Soundproofing Materials:

The Mini Stirrer's casing and internal components are often lined with soundproofing materials, such as noise-absorbing foams or specialized coatings. These materials effectively dampen the sound produced during operation, providing a quieter working environment. Careful selection of these materials is crucial to strike a balance between noise reduction and maintaining the stirrer's durability and functionality.

3.Isolation Pads:

To prevent vibrations from being transmitted to the surface on which the Mini Stirrer is placed, manufacturers incorporate high-quality rubber or silicone isolation pads. These pads act as shock absorbers, isolating the stirrer from the work surface and reducing noise transmission. Precision in the design and placement of these pads ensures optimal noise reduction without compromising stability.

4.Precision Engineering:

Every component within the Mini Stirrer is engineered with precision. This includes the gears, bearings, and moving parts. By using high-quality materials and employing precision manufacturing techniques, friction is minimized, resulting in smoother operation and significantly reducing noise. Lubricants are carefully chosen and applied to further decrease friction and noise generation.

5.Variable Speed Control:

Mini Stirrers often come with variable speed control settings. Users can adjust the stirring speed to match the viscosity of the solution being stirred. Operating the stirrer at an appropriate speed not only ensures efficient mixing but also reduces unnecessary noise. This customization allows users to find the optimal balance between speed and noise for their specific applications.

6.Regular Maintenance:

Manufacturers provide guidelines for regular maintenance, including lubrication of moving parts. Routine lubrication ensures that the internal components operate smoothly, reducing wear and tear that can lead to increased noise levels over time. Proper maintenance, as outlined in the user manual, preserves the stirrer's performance and keeps noise levels at a minimum throughout its lifespan.

7.Customer Feedback:

Manufacturers value feedback from users. Insights gained from customer experiences are invaluable in the continuous improvement of Mini Stirrer models. Manufacturers actively collect and analyze this feedback to identify areas for enhancement, including noise reduction. Customer input often leads to innovations in design and technology, resulting in quieter and more efficient Mini Stirrers in subsequent iterations.

Certification: CE ROHS LFGB FDA

Voltage: DC 3V

Material: 304 Stainless steel + ABS

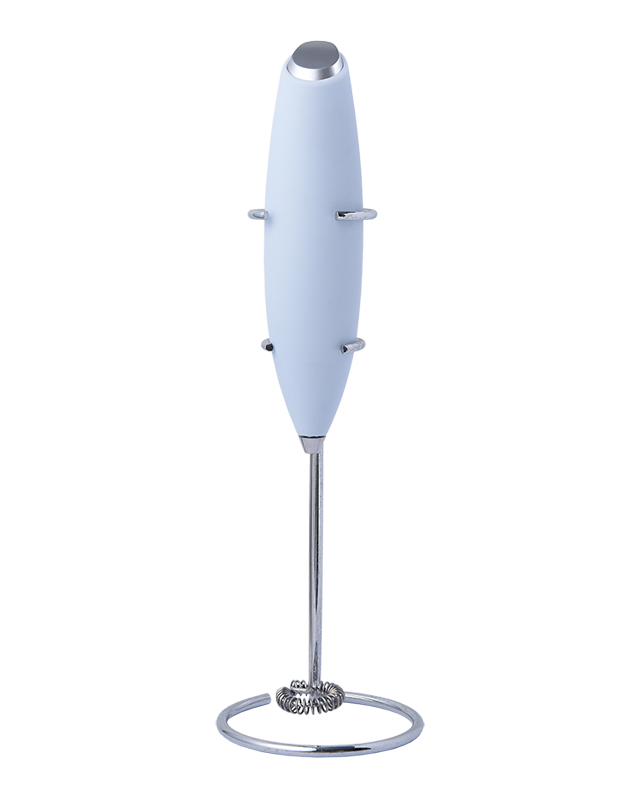

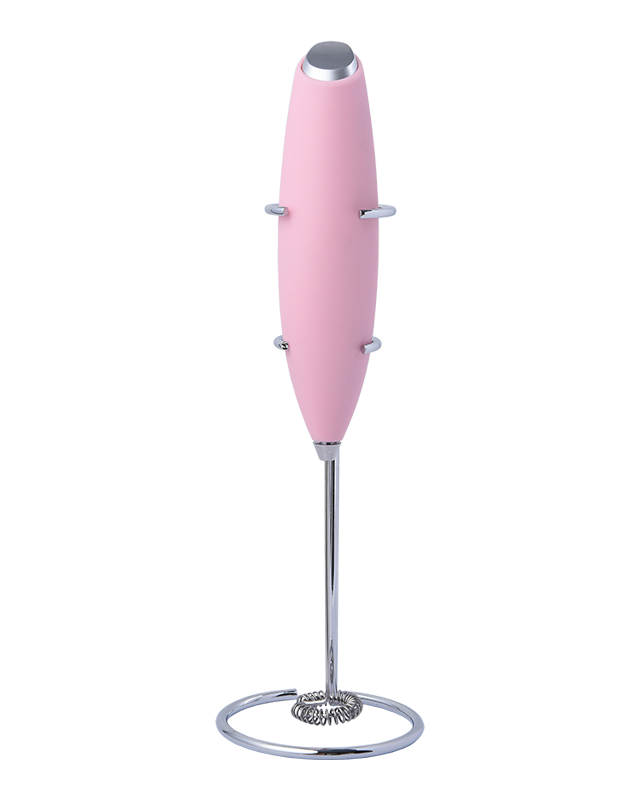

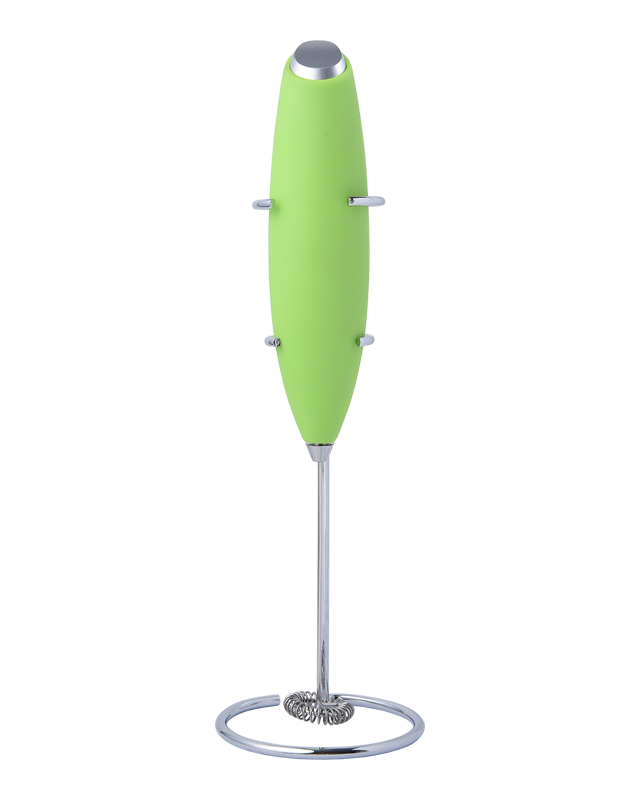

Color: Any colors can be done as custom

Product weight: 102g

Housing: Plastic ABS

Rated Power: 2W

Application: Frothing milk, Whisking coffee or beverages, Beating eggs

English

English

Français

Français

Español

Español

Deutsch

Deutsch

日本語

日本語